Guide to Buying the Best Gear Cutters Online

Gears were made by hand from old times until the eighteenth century when automation became far-reaching in Europe with the presentation of tickers and different machines. During the Modern Unrest, machines committed to making gears were created one after another.

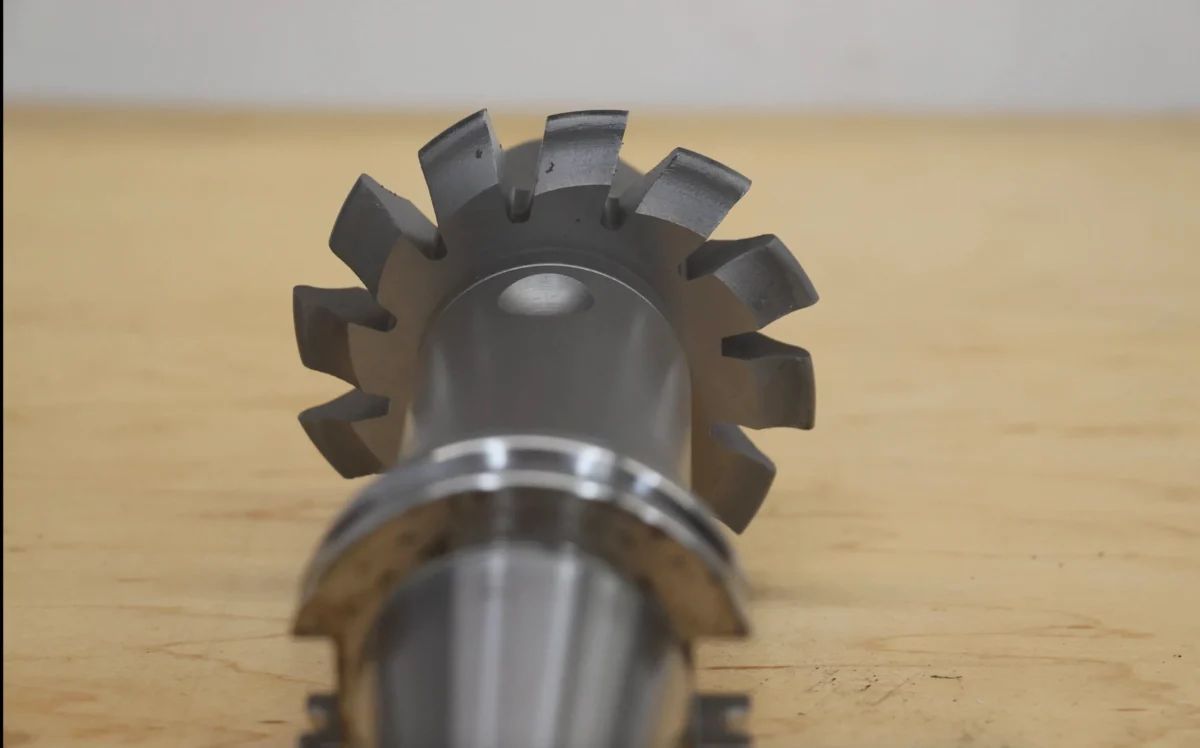

In gear making, steel chambers are initially cut into round plates, which are then machined into spaces before going through the cycles of Hobbing, extinguishing, and crushing of the surfaces and the teeth. Today, each interaction utilizes an NC gear fabricating machine, for example, a Hobbing machine. These stuff fabricating machines permit administrators to effectively change the slicing speed and to determine the number of stuff teeth.

Lately, composite handling machines given machines are becoming normal. Every gear finishing tools manufacturers use these composite handling machines to finish the cycles from proposing and processing to Hobbing, limiting changeovers and considering more prominent proficiency in gear creation.

Significant Sorts of Cog wheels

Gears come in different shapes and sizes, and they all need devoted machines for machining. Pinion wheels can be comprehensively arranged into prod cog wheels and slant gears, with spike gear cutting machines and angle gear cutting machines as the particular stuff cutting machines, separately.

Different cog wheels incorporate helical cog wheels, which have winding teeth; rack and pinion frameworks, which make an interpretation of rotational movement to direct movement; and worm gears, which move movement in 90-degree points.

- Spur gear

- Helical gear

- Bevel gear

- Rack and pinion

- Worm and worm wheel

Normal Stuff-Cutting Strategies

The most well-known techniques for cutting stuff teeth are the creating strategy and the shaping strategy.

With the creating technique, the rack shaper is pushed against the plate that will turn into stuff, cutting along the outline of the circle. While this strategy makes it conceivable to create high-accuracy equips, the significant expenses are a detriment. Accuracy parts can then be done by crushing or sharpening after the teeth have been cut. The creating strategy is generally embraced in gear cutting, and the most well-known machine utilized is the Hobbing machine.

Then again, the framing strategy utilizes a processing machine outfitted with a cutting instrument with a similar shape as the furrows of the ideal stuff. This strategy empowers large-scale manufacturing of cogwheels without the requirement for committed creation machines.

Alternate approaches to causing cogwheels incorporate molding for creating slope cog wheels, and plastic shaping cycles like manufacturing.

NC Stuff Creation Machines

Among the numerous NC gear shaving cutter price, the NC Hobbing machine is perhaps the most generally utilized type and is broadly utilized in the vehicle business. Various models have been created chasing after accuracy and creation productivity, further engaging stuff creation.

Other NC gear creation machines incorporate molding machines, which can accomplish accuracy teeth cutting; crushing machines, which toil extinguished gears; sharpening machines, which clean the outer layer of cog wheels in the wake of extinguishing; and shaving machines, which finish the pinion wheels. These machines are completely used to deliver accurate gears.