Top Benefits of Using HMI/SCADA Software in Your Factory

Factories across India are embracing digital change, and Aveva Edge is making a difference. For factory managers, owners, and engineers, choosing the right HMI/SCADA software is a smart move for long-term growth. In this guide from PIMA Industrial, you’ll see why investing in user-friendly automation brings clear, real-world benefits. You’ll learn how Aveva Edge helps factories save time, cut costs, and work smarter every day.

What Is HMI/SCADA Software?

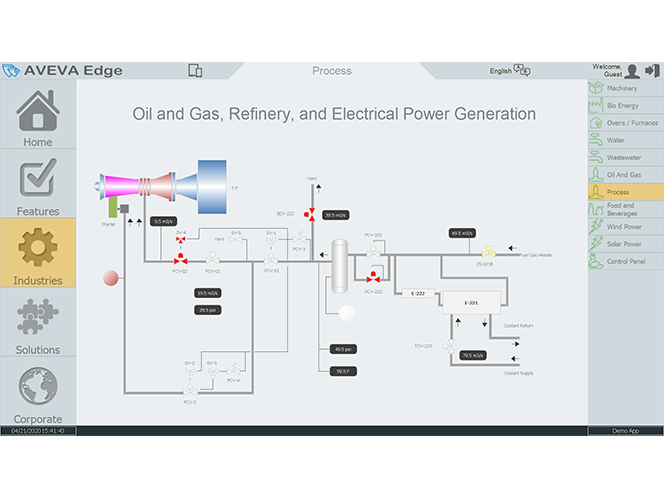

HMI stands for Human Machine Interface, and SCADA means Supervisory Control and Data Acquisition. Together, they help people see, control, and manage equipment in a factory. Aveva Edge gives you these tools, so you can watch processes in real time and react quickly if something goes wrong. With the right HMI/SCADA, you avoid breakdowns, reduce manual work, and gain full visibility.

Key Benefits of Using Aveva Edge HMI/SCADA Software

1. Better Visibility and Control

With Aveva Edge, managers see what’s happening across the plant at any moment. Dashboards show machine status, production rates, and alerts. If there’s a problem, you know right away. That means less downtime and fewer surprises. Live data lets operators make fast decisions and keep things on track.

2. Improved Productivity

Factories using Aveva Edge often see a jump in output. Why? The software automates repetitive tasks, tracks machine health, and schedules maintenance at the right time. Teams can do more with fewer mistakes. According to a 2024 manufacturing survey, companies using modern SCADA platforms reported up to 25% fewer production delays.

3. Cost Savings

Manual monitoring costs money and time. Aveva Edge helps cut waste by quickly spotting faults and inefficiencies. Data-driven decisions mean fewer resources are wasted. Energy usage drops, raw material losses fall, and repair bills shrink.

Also read: Schneider Electric Distributor for Your Energy Needs

4. Stronger Security and Compliance

Aveva Edge includes security features like access controls and audit trails. Only approved staff can access sensitive information. The software helps your factory follow safety and industry standards. In many sectors, meeting compliance rules protects against heavy penalties.

5. Easy Integration and Scalability

Factories grow and change over time. Aveva Edge works well with different equipment, sensors, and cloud platforms. Whether you have a small setup or a huge plant, you can add new machines or upgrade software with minimal fuss. This flexibility helps your business stay ready for future demands.

6. Real-Time Reporting and Analytics

With built-in analytics, you get detailed reports on performance and quality. Teams spot trends and solve problems before they turn serious. For example, if energy use is creeping up, Aveva Edge shows you where to look. These insights boost efficiency and keep your factory competitive.

7. Remote Monitoring and Mobile Access

Managers no longer have to be on the shop floor to check on operations. Aveva Edge lets you view data, alarms, and trends from your phone or laptop, even when you’re away. This mobility saves time and allows quick action in urgent situations.

8. Easy to Learn and Use

One of the strongest points of Aveva Edge is its user-friendly interface. Employees learn to use the system quickly, with minimal training. This lowers the barrier for new staff and makes daily tasks less stressful.

Who Should Use HMI/SCADA Software?

Any factory that wants to improve efficiency, reduce downtime, and gain better control can benefit. This includes industries such as food processing, automotive, chemicals, and packaging. Both small and large plants will see returns from switching to a modern platform like Aveva Edge.

Real-World Case Study

A leading food processing plant in South India partnered with PIMA Industrial to upgrade their old monitoring system. After switching to Aveva Edge, the factory cut machine downtime by 30% and reduced energy costs by 15% within a year. The team could predict maintenance needs and solve issues before they turned into big problems. Productivity climbed, and staff felt more in control.

Latest Trends in HMI/SCADA for Factories

According to a 2024 report by MarketsandMarkets, the global SCADA market is set to reach $15.5 billion by 2028, growing at a steady pace. Key trends include increased use of cloud platforms, artificial intelligence, and remote access. Aveva Edge stays current with these shifts, giving factories the tools they need to compete.

Pros & Cons of Using Aveva Edge HMI/SCADA

Pros:

-

Real-time monitoring and alerts

-

Reduced downtime and improved safety

-

Cost savings on maintenance and energy

-

Easy integration with existing equipment

-

Mobile access for managers on the go

-

Simple, user-friendly dashboards

Cons:

-

Initial setup can require expert help

-

Older machines may need adapters or upgrades

-

Staff training is needed for best results

Frequently Asked Questions

What is Aveva Edge?

Aveva Edge is flexible HMI/SCADA software that helps factories control and monitor equipment.

How does it help save costs?

By reducing manual checks, preventing breakdowns, and lowering energy use, it leads to real savings.

Where can you use it?

Aveva Edge works in many industries, from food processing to heavy manufacturing.

Why choose PIMA Industrial?

PIMA Industrial offers setup, support, and local knowledge to help you get the most out of Aveva Edge.

Will my factory need upgrades?

Most modern equipment works with Aveva Edge, but some older systems may need adapters.

Conclusion

Switching to Aveva Edge HMI/SCADA software gives your factory a strong edge in today’s market. With clear data, fewer breakdowns, and simple tools, your team can focus on what matters most—growth, safety, and smooth operations. PIMA Industrial is here to help you start, from first consultation to ongoing support. Take the next step and see how your business can run better, faster, and smarter. Ready to learn more? Share your thoughts below or reach out for a free demo