Electronic assemblies: Advanced processes explained!

Contemporary electronics form the foundation of industrial innovation – ranging from smartphones and car systems to medical equipment and space technology. The core of these innovations is a key driver: electronic assemblies. Innovation and precision in electronic assembly processes dictate the efficiency, functionality, and reliability of systems we utilize every day.

What Are Electronic Assemblies

They entail the process of mounting different electronic components such as resistors, capacitors, semiconductors, and integrated circuits on a printed circuit board (PCB) to form working electronic systems. The assembly processes have advanced a great deal, keeping up with the requirement for smaller, quicker, and more effective electronic devices.

Through the expertise of superior electronic assembly processes, manufacturers are able to customize products for better performance, reliability, and environmentally friendly manufacturing.

Advanced Processes in Electronic Assemblies

The technology of advanced electronic devices relies on state-of-the-art assembly techniques. This is what the most important phases and developments that make waves throughout the industry are:

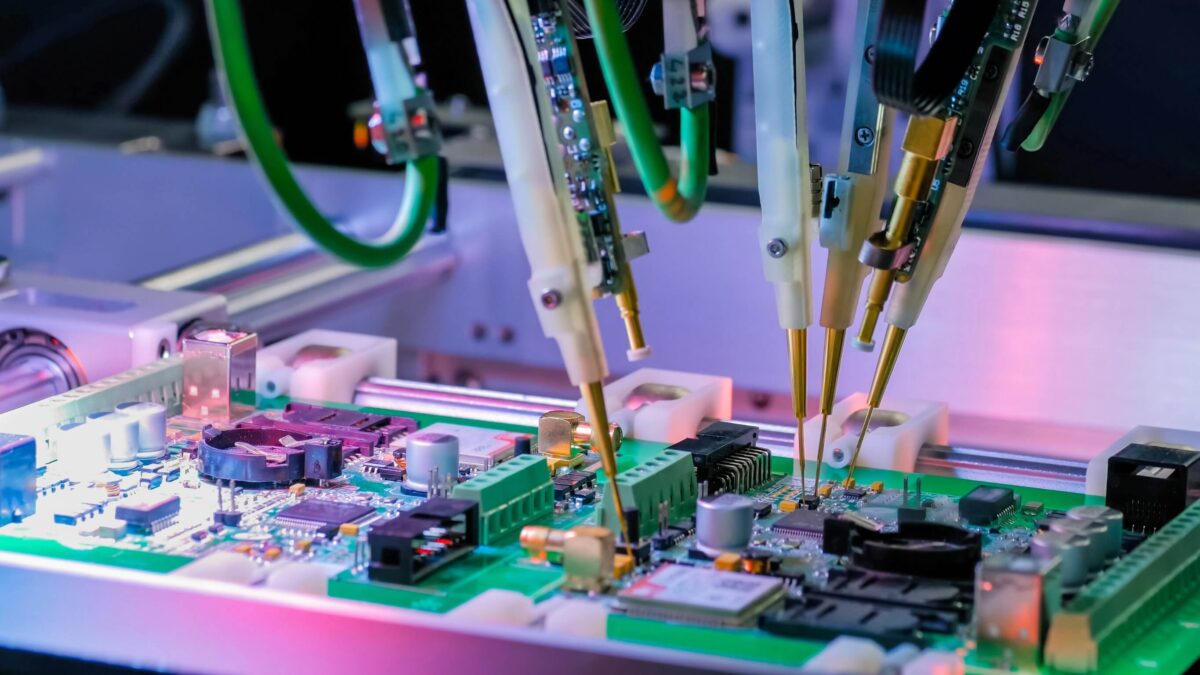

High-Precision Manufacturing Equipment

Modern electronics depend on accurate manufacturing. Advanced equipment places components within micrometers of their target positions. Every step of the process uses automation, computer-controlled mechanisms, and robotics to achieve unparalleled accuracy and repeatability.

Surface Mount Technology (SMT)

SMT is the standard process for mounting small, intricate electronic components on PCBs. Unlike inserting components via holes, SMT is done by placing components directly on the board’s surface.

Main Benefits:

- Enables device miniaturization

- Improves signal integrity for high-frequency signals

- Cost savings through accelerated assembly operations

Through-Hole Technology (THT)

Despite SMT’s prevalence, some components (e.g., connectors or large capacitors) continue to make use of Through-Hole Technology. THT consists of placing component leads into pre-drilled holes on a PCB and soldering them onto the board. The method provides excellent mechanical strength, which is well suited for products that are liable to being stressed many times, like industrial machinery.

Reflow Soldering

Soldering is an essential process, mounting components onto the PCB and establishing electrical connections. Reflow soldering is a sophisticated technique that is commonly employed in SMT.

How It Works:

- Solder paste is deposited on the PCB at specific locations using a stencil.

- Components are mounted onto the solder paste using pick-and-place machines.

- The board is then heat-treated inside a reflow oven, fusing the solder and forming secure connections.

Reflow soldering’s disciplined heat profile reduces defects like solder bridges, cold joints, or misaligned components.

Inspection and Quality Control

There is no assembly without careful inspection and testing to achieve functionality and reliability.

Automated Optical Inspection (AOI)

AOI employs high-resolution cameras to detect assembly flaws such as misaligned components, solder defects, or missing components. The operation enables quick, non-destructive quality control.

X-Ray Inspection

For highly dense or multilayer PCBs, X-ray inspection reveals concealed faults such as internal misalignments or solder joints voids that the naked eye cannot see.

Functional Testing

Functional testing imitates in-use conditions to ensure the overall functionality of the assembled PCB. This sophisticated phase detects flaws missed by visual inspection, including electrical shorts or circuit failure.

Conformal Coating Application

To shield electronic assemblies against environmental threats such as moisture, dust, and chemicals, conformal coatings are used. These particular coatings create a protective film over the PCB but also enable it to function effectively.

Sophisticated conformal coating operations use robotic machinery for accurate and reproducible application so that there is an even coating with no voids or overspray.

Flex and Rigid-Flex Circuit Assembly

New devices such as wearables and healthcare products usually need flexible circuits to fit into small, non-traditional areas. Flex circuits and rigid-flex circuits (hybrid of rigid and flex parts) are produced using a proprietary assembly process.

The circuits necessitate special handling, masking, and soldering skills for avoiding damage during assembly, which speaks volumes about the ingenuity involved in high-end electronic assemblies.

Printed Electronics and Additive Manufacturing

Printed electronics, a revolutionary innovation, entail the production of parts such as conductive traces and sensors through additive manufacturing methods. They incorporate the use of special inks filled with conductive substances (such as silver or carbon) to deposit electronics straight onto flexible substrates.

Printed electronics are revolutionizing progress toward lighter, wearable, and foldable devices, a giant leap in electronic assembly techniques.

Thermal Management Systems

Miniaturization of electronics, in most cases, yields increased power density, which may cause overheating. To mitigate this, high-end electronic assemblies employ thermal management solutions such as heat sinks, thermal vias, and insulating materials that ensure efficient dissipation of heat and limit the degradation of performance over time.

Cleanroom Assembly

For industries such as aerospace, medical devices, and semiconductors, ultra-clean environments without dust particles are important to prevent contamination at the time of assembly. Cleanroom facilities embrace sophisticated air control systems and strict protocols to preserve the purity of sensitive parts and assemblies.

Conclusion

Sophisticated electronic assembly techniques are the impetus for much of the life-enhancing technology we see every day. From enhanced manufacturing accuracy to new inspection techniques, these innovations create possibilities in contemporary electronics previously unthought of.

Whether you’re designing wearable fitness trackers, aerospace systems, or revolutionary medical implants, understanding these practices can elevate electronic assemblies to their full potential. By combining cutting-edge techniques with a forward-looking approach, businesses can harness the true power of advanced electronics.

The next time you grab a shiny, high-performance electronic device, consider the phenomenal engineering and careful craftsmanship that went into its making. Behind every technological innovation lies a tale of cutting-edge processes, precision, and skill coming together harmoniously.