Efficiency and Quality with Tunnel Pasteurization Equipment for Juice and Beverage Processing

Introduction

In the ever-evolving beverage industry, maintaining product quality, safety, and shelf stability is crucial to meet both regulatory requirements and consumer expectations. One of the most effective solutions for achieving these goals is tunnel pasteurization equipment. Especially significant in the production of pasteurized fruit juices and beverages, tunnel pasteurization equipment helps manufacturers control microbial activity while preserving the desired flavor and freshness of the final product. As consumer demand for both refrigerated and shelf-stable beverages grows, tunnel pasteurization equipment has become a cornerstone of modern juice and beverage processing.

Understanding Tunnel Pasteurization Equipment

Tunnel pasteurization equipment is a sophisticated thermal processing system that uses a series of temperature-controlled zones to gradually heat and cool packaged beverages. This ensures that harmful microorganisms are effectively eliminated without compromising the quality of the product. The entire process happens in a sealed, tunnel-like chamber, hence the name.

Tunnel pasteurization equipment is commonly used for products packaged in glass or PET bottles and aluminum cans, providing an ideal method for extending shelf life and maintaining flavor integrity. From small tunnel pasteurizers for R&D to large-scale systems for full production, manufacturers rely on this technology to deliver consistent results.

The Role of Tunnel Pasteurization Equipment in Juice and Beverage Processing

Juice and beverage processors choose their method of pasteurization based on how the final product will be distributed and the image they want to portray to consumers. High-quality, fresh-tasting beverages are often refrigerated and require processing that supports extended shelf life without altering flavor. This is where tunnel pasteurization equipment truly shines.

Tunnel pasteurization equipment allows manufacturers to:

- Maintain the natural taste and nutritional value of juices.

- Ensure the elimination of spoilage organisms and pathogens.

- Offer products with longer shelf lives, both refrigerated and non-refrigerated.

- Optimize the convenience and safety of ready-to-drink beverages.

Benefits of Using Tunnel Pasteurization Equipment

Investing in tunnel pasteurization equipment provides several key benefits that make it indispensable in juice and beverage manufacturing:

1. Consistent Pasteurization

Unlike manual or batch systems, tunnel pasteurization equipment ensures uniform thermal treatment for every unit. This reduces the risk of under-processing or over-processing, guaranteeing a consistent quality in every batch.

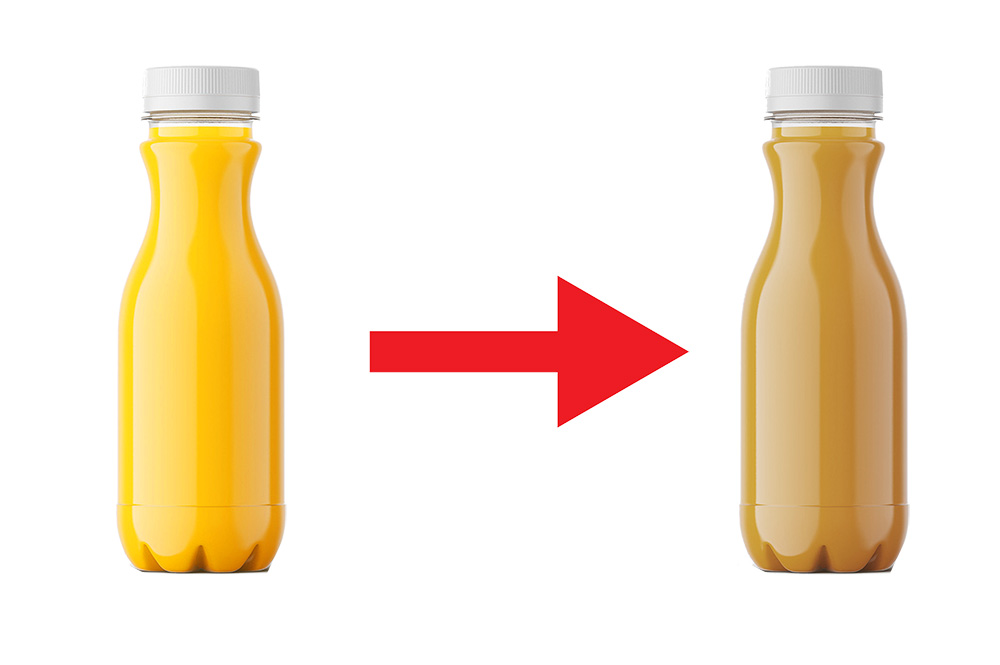

2. Extended Shelf Life

By eliminating microbes effectively, tunnel pasteurization equipment helps manufacturers extend product shelf life, especially important for products intended for non-refrigerated distribution.

3. Improved Safety

The high heat treatment provided by tunnel pasteurization protects consumers by reducing the risk of foodborne illnesses. It aligns with food safety regulations and quality standards required globally.

4. Preservation of Flavor and Nutrients

Small tunnel pasteurizers used in R&D help simulate large-scale production without compromising taste or nutrition, giving beverage companies a competitive edge when testing new recipes or entering niche markets.

5. Energy Efficiency

Modern tunnel pasteurization equipment is designed to maximize energy efficiency, utilizing heat recovery systems to reduce energy consumption and lower operational costs.

Applications in Pasteurized Fruit Juices and Beverages

The application of tunnel pasteurization equipment extends across a wide variety of fruit juices and beverages. Whether for cold-pressed juices, fruit-based drinks, or flavored waters, tunnel pasteurization provides the flexibility and reliability that manufacturers need.

Cold Fill vs. Hot Fill vs. Tunnel Pasteurization

There are several methods for processing juice and beverage products, including hot fill, aseptic fill, and tunnel pasteurization equipment. Each has its benefits:

- Hot Filling: Involves filling products at high temperatures, then sealing them. This method can affect flavor and is best suited for products like fruit concentrates.

- Aseptic Processing: Used for shelf-stable products, requiring sterilized packaging and environments. More complex and cost-intensive.

- Tunnel Pasteurization Equipment: Ideal for products requiring refrigerated distribution or moderate shelf stability. Maintains flavor better than hot filling and offers simpler integration than aseptic processing.

Why Tunnel Pasteurization Equipment Is Ideal for R&D

Research and development are vital stages in the beverage production lifecycle. Small tunnel pasteurizers, such as those provided by MicroThermics, enable companies to test new products in small batches with the same precision and quality as large-scale operations.

Using tunnel pasteurization equipment in R&D allows teams to:

- Perfect recipes before large-scale production.

- Simulate production line outcomes on a smaller scale.

- Ensure compliance with food safety and quality benchmarks.

- Explore new product concepts with minimized waste and cost.

How MicroThermics Supports Tunnel Pasteurization Equipment Usage

MicroThermics, a trusted name in thermal processing solutions, provides cutting-edge tunnel pasteurization equipment tailored to the needs of juice and beverage manufacturers. Whether a company is exploring cold-filled refrigerated juices or launching a new shelf-stable drink, MicroThermics delivers R&D and production support through:

- Advanced small tunnel pasteurizer systems.

- Expertise in pasteurized fruit juice processing.

- Customized support for beverage process development.

- Equipment that mimics real-world manufacturing conditions.

MicroThermics bridges the gap between innovation and full-scale production, ensuring beverage companies can bring high-quality, safe, and flavorful products to market faster.

Meeting Consumer Expectations with Tunnel Pasteurization Equipment

Today’s consumers expect beverages that are not only flavorful but also safe, convenient, and consistent. Tunnel pasteurization equipment empowers producers to meet these expectations by:

- Providing reliable thermal processing that preserves product freshness.

- Supporting environmentally friendly operations through energy-efficient technology.

- Allowing the creation of beverages that can be stored without refrigeration.

From niche juice brands to large beverage corporations, tunnel pasteurization equipment plays a critical role in ensuring product integrity from production to the point of sale.

Future Trends in Tunnel Pasteurization Equipment

The future of tunnel pasteurization equipment looks promising with several key trends shaping the industry:

- Automation and IoT Integration: Enhancing precision and reducing labor costs.

- Modular Systems: Providing scalable solutions for growing businesses.

- Eco-Friendly Designs: Emphasizing water and energy conservation.

- Custom R&D Solutions: Facilitating innovation in new beverage types.

As the demand for safe, convenient, and diverse beverages continues to grow, tunnel pasteurization equipment will remain a core technology for manufacturers focused on quality and compliance.

The Bottom Line

Tunnel pasteurization equipment is a game-changer in the juice and beverage processing industry. It ensures product safety, extends shelf life, and maintains flavor—all while supporting scalable and sustainable production. Whether for R&D or full-scale manufacturing, tunnel pasteurization equipment from trusted providers like MicroThermics empowers companies to deliver superior beverages that meet both market demands and regulatory standards. For any beverage manufacturer aiming to produce high-quality, pasteurized fruit juice or ready-to-drink beverages, investing in reliable tunnel pasteurization equipment is not just an option—it’s a necessity.

Would you like a downloadable PDF version of this blog for offline sharing or use on your website?