Choosing the Right Capacitor Discharge Welding Machine Supplier for Your Business Needs

When it comes to precision welding, especially in industries like electronics, automotive, and aerospace, capacitor discharge welding (CDW) machines are an essential piece of equipment. CDW machines are renowned for delivering high-quality welds quickly, making them a preferred choice for applications involving thin materials and delicate components. However, to maximize the benefits of capacitor discharge welding, choosing the right capacitor discharge welding machine supplier is crucial. This article explores key factors to consider when selecting a supplier and why Taylor-Winfield Technologies is a leading name in the industry.

Understanding Capacitor Discharge Welding Machines

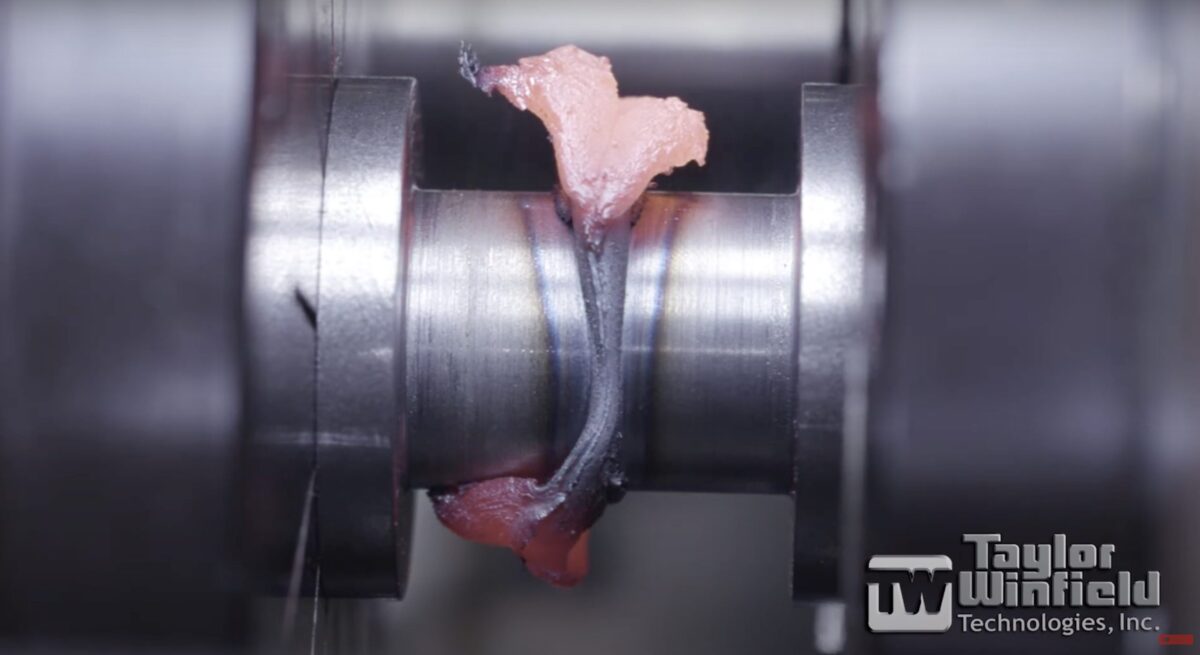

Capacitor discharge welding is a unique process that utilizes stored energy from capacitors to create a controlled, high-intensity current in a fraction of a second. This allows for precise, low-heat welds, making it ideal for welding small, thin, or coated materials without causing damage. Applications of CDW include welding fasteners, studs, and other components onto surfaces where minimal heat distortion is critical.

The efficiency, speed, and quality of capacitor discharge welding make it a preferred method in sectors that demand precision. However, the quality of your welding operations heavily depends on the machine and supplier you choose.

Factors to Consider When Choosing a Capacitor Discharge Welding Machine Supplier

- Industry Expertise: Look for suppliers with extensive experience in the welding industry. A knowledgeable supplier can offer guidance and solutions tailored to your specific welding needs, ensuring you get the most out of your investment.

- Product Quality and Reliability: The quality of the machine directly affects the performance of your welding processes. Choose a supplier that manufactures robust, reliable machines using high-quality components to ensure consistent results and minimize downtime.

- Customization and Flexibility: Your industry may have unique welding requirements. A good supplier should offer customizable machines, from weld settings to machine configurations, ensuring the equipment meets your specific production needs.

- Technical Support and After-Sales Service: A reputable supplier provides comprehensive technical support, including installation, maintenance, and troubleshooting. Excellent after-sales service ensures your machines remain in optimal condition, reducing operational disruptions.

- Innovation and Advanced Technology: The welding industry is continually evolving, and the best suppliers invest in research and development to stay ahead. Look for suppliers that offer the latest technology and innovative solutions to improve your welding efficiency and quality.

- Cost-Effectiveness: While initial costs are important, long-term value is crucial. A reliable supplier will offer cost-effective machines that provide excellent performance, reduce maintenance costs, and minimize downtime, ensuring a high return on investment.

Benefits of Partnering with the Right Capacitor Discharge Welding Machine Supplier

- Enhanced Productivity: A top-tier CDW machine can significantly improve your production speed and efficiency, leading to higher output and reduced operational costs.

- Superior Weld Quality: Machines from reputable suppliers deliver high-quality, consistent welds, reducing the risk of defects and ensuring your products meet industry standards.

- Reduced Downtime and Maintenance: Reliable machines from established suppliers are less prone to breakdowns. In the rare event of an issue, prompt technical support ensures minimal downtime.

- Scalability: As your business grows, your needs will evolve. A good supplier provides scalable solutions that adapt to your changing requirements, from machine upgrades to additional automation features.

- Cost Savings: High-quality machines lead to long-term savings through reduced maintenance, lower defect rates, and higher productivity.

Why Taylor-Winfield Technologies is Your Go-To Capacitor Discharge Welding Machine Supplier

Taylor-Winfield Technologies is a leading capacitor discharge welding machine supplier, offering state-of-the-art machines that cater to diverse industry needs. Here’s why Taylor-Winfield stands out:

- Decades of Experience: With over 100 years of experience in welding technology, Taylor-Winfield provides expert solutions tailored to your specific requirements.

- Cutting-Edge Innovation: Their commitment to research and development ensures that you receive the latest in welding technology, enhancing your production quality and efficiency.

- Custom Solutions: Taylor-Winfield offers fully customizable welding machines that can be tailored to meet your exact specifications, ensuring optimal performance.

- Comprehensive Support: From installation to ongoing maintenance, Taylor-Winfield offers unmatched support to keep your machines running smoothly and efficiently.

- Proven Reliability: Known for high-quality and durable machines, Taylor-Winfield is a trusted name in the industry, ensuring you receive reliable equipment backed by exceptional service.

Conclusion

Selecting the right capacitor discharge welding machine supplier is essential for maximizing the efficiency and quality of your welding operations. Taylor-Winfield Technologies combines industry expertise, innovative technology, and superior customer service to provide the best CDW machines on the market. Contact Taylor-Winfield today to explore their range of capacitor discharge welding machines and find the perfect solution for your business.