5 Reasons to Use a Metal Core PCB (MCPCB)

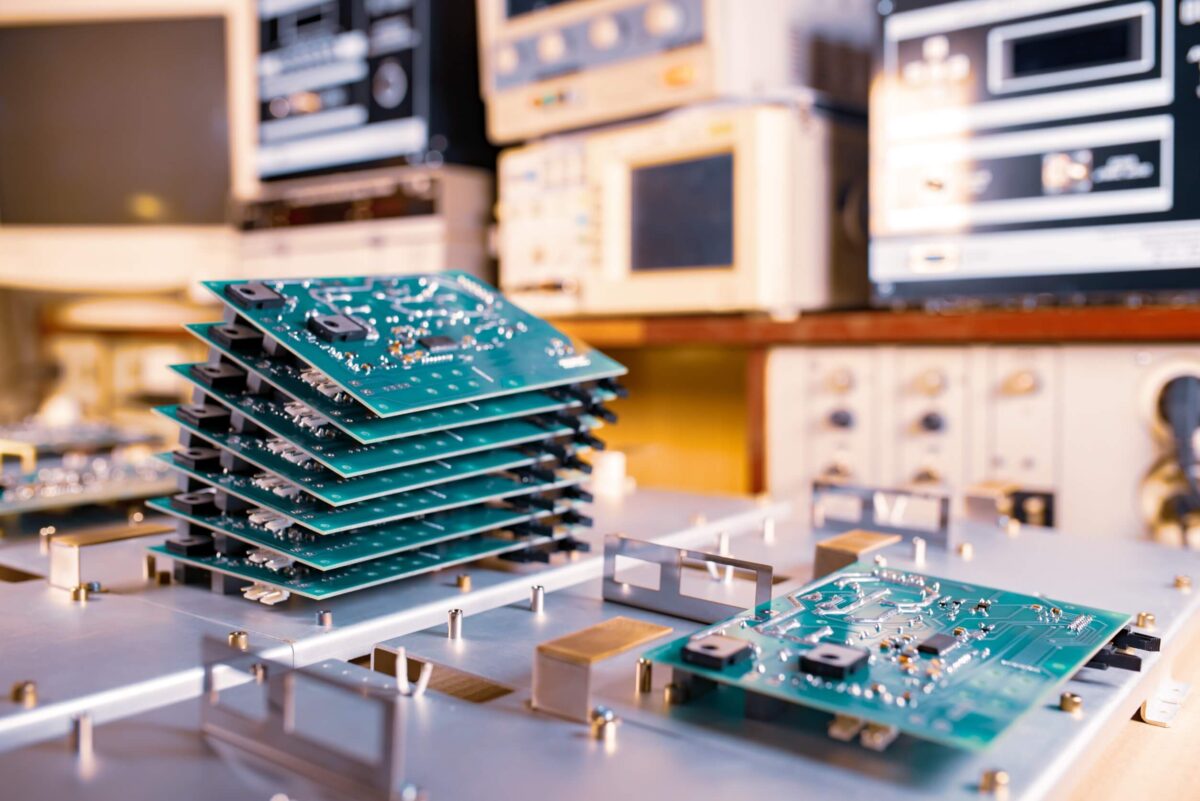

Printed circuit boards or PCBs form the pillar of contemporary electronics, driving everything from home appliances to sophisticated aerospace systems. Although classic PCBs of fiberglass or resin are still widely used for most applications, engineers and manufacturers are now increasingly opting for metal core PCB (printed circuit board with metal at its core).

Why the transition to metal core PCBs? Their distinctive structure provides higher performance, reliability, and longevity in numerous applications.

5 reasons to utilize a metal core PCB

- Better Heat Dissipation

High-power devices like LEDs or power converters tend to produce large quantities of heat. Excessive heat, if not properly managed, can cause damage to components, reduce performance, and reduce the lifespan of the device.

Metal core PCBs or MCPCBs excel in heat dissipation due to their metallic core, commonly made from aluminum or copper. This core acts as a thermal conductor, efficiently transferring heat away from heat-sensitive components and into a heat sink or the surrounding environment.

For example, in LED lighting circuits, MCPCBs keep the LEDs cool, which preserves their brightness and their lifespan. This better heat dissipation makes metal core PCBs priceless in applications that require high-performance thermal management.

- Increased Durability

Equipment that works in rugged environments, like industrial equipment or automotive applications, needs PCBs that can survive mechanical stress, temperature variations, and chemical or moisture exposure.

MCPCBs are significantly stronger than their fiberglass equivalents. Due to their metal substrate, they have outstanding resistance to vibration and physical shock, providing dependability even under the most rigorous conditions.

For instance, in automotive use, metal core PCBs can withstand the repeated vibrations of a traveling vehicle and temperature fluctuations inherent in engine operation without sacrificing performance. This strength makes them a reliable option for mission-critical use.

- Improved Electrical Performance

When it comes to high-powered or high-frequency designs, electrical performance can be a make-or-break factor for a product’s success. Lack of performance can result in signal loss or decreased efficiency, affecting the end-user experience.

MCPCBs have lower thermal resistance and improved electricity conductivity. Their capacity to offer stable electrical pathways guarantees maximum performance. In high-frequency circuits, the minimized risk of energy dissipation enhances efficiency while preventing possible overheating or electrical problems.

This benefit has rendered metal core PCBs a preferred choice for advanced technologies such as power electronics, telecom systems, and contemporary computing devices.

- Compact and Lightweight Designs

Compact, lightweight designs are essential in the electronics industry today, with portable and slim products being the norm. Whether a slim laptop, a leading-edge smartphone, or a portable medical device, reducing bulk without compromising performance is a primary objective.

MCPCBs make this possible through fewer layers and the application of high-performance materials. They lower the need for other cooling parts, such as heat sinks or fans, by their very high thermal conductivity. This savings in materials is then reflected in designs that are more compact, stream-lined, and cost saving when produced.

An example in real life? Consider LED lights in small electronic devices. The synergy of miniature size, light weight, and effective heat management offered by an MCPCB is imperative for their functionality.

- Cost-Effective Long-Term Solution

Although metal core PCBs may have a slightly higher initial cost than standard PCBs, they tend to be more economical in the long run. Their increased durability minimizes the risk of device failure and expensive repairs or replacements. Moreover, better heat management can result in increased energy efficiency, which is especially crucial in continuously operating devices or high-power-consuming devices.

Consider data centers, for instance. Data storage and servers create a lot of heat. Using metal core PCBs, however, these systems can run more efficiently, use less carbon, and save energy. All these make MCPCBs a valuable investment for use in applications where performance over the long term is required.

Conclusion

Metal core PCBs represent more than simply a replacement for the older PCBs. They are actual facilitators of innovation, particularly in applications that require high-performance, long-lasting solutions. With better thermal dissipation, improved longevity, better electrical properties, reduced packaging possibilities, and cost advantages over the long term, MCPCBs are leading the way into next-generation electronic applications.

If you have an upcoming project with high-power components, harsh operating environments, or small designs, a metal core PCB may be the improvement your product demands. Begin to discover the boundless potential of MCPCBs today and maintain your competitive advantage in your industry with smarter and stronger PCB solutions.